هل بلاستيك PET آمن؟ اكتشف المواد المفضلة للتغليف الغذائي

يتم استهلاك أكثر من 500 مليار زجاجة بلاستيكية من نوع PET في جميع أنحاء العالم كل عام. إنها آمنة وقابلة للنقل وإعادة التدوير، لكن قلة قليلة من الناس تفهم حقًا هذا النوع من المواد التي ترافقنا يومًا بعد يوم.

في العصر الحالي الذي يسعى فيه الجميع إلى الصحة والاستدامة، أصبحت سلامة التعبئة البلاستيكية محور اهتمام مشترك بين المستهلكين والعلامات التجارية. وبصفتنا رائدين في صناعة التعبئة، فإننا ندرك تمامًا الأهمية التي تولونها لسلامة المنتجات. وعند اختياركم زجاجة بلاستيكية مخصصة، من المهم أن تفهموا طبيعة المادة المستخدمة.

مادّة البولي إيثيلين تيريفثاليت (PET)، التي تبدو في ظاهرها مادةً بلاستيكيةً عادية، تحمل مسؤولية كبيرة فيما يتعلق بعبوات الأغذية والمشروبات على مستوى العالم. فمنذ زجاجات المياه المعدنية الفاخرة وصولاً إلى حاويات الأدوية، ومن تغليف الزيوت النباتية حتى قوارير وعلب مستحضرات التجميل، أصبحت مادّة PET المادة المفضّلة لحلول التغليف المخصصة بفضل خصائص السلامة والأداء البيئي الممتازة التي تتمتع بها.

01ماذا يعني بلاستيك PET؟

البولي إيثيلين تереفتالات (PET) ,الاسم الكامل لها هو بولي إيثيلين تيريفثاليت، ويُشار إليها كيميائيًا باسم بولي إيثيلين تيريفثاليت، وتُعرف غالبًا باسم البوليستر. وقد أصبح هذا النوع من البوليمرات ذات الوزن الجزيئي العالي المادة الأساسية التي يعتمد عليها قطاع صناعة التغليف على المستوى العالمي.

من منظور التركيب الكيميائي، تحتوي بوليمرات الحيوانات الأليفة على مجموعات أليفاتية، مما يمنحها بعض الخصائص الهيدروفيلية، وهي خاصية مهمة بشكل خاص في الإنتاج والمعالجة. في صناعة التعبئة والتغليف، يُستخدم على نطاق واسع gf-pet (بوليستر مقوى بالألياف الزجاجية)، ويُستخدم بشكل رئيسي لتصنيع أجسام الزجاجات بمختلف المواصفات.

عندما تمسك بزجاجة مشروبات شفافة وخفيفة الوزن، فإنك تمسك مادة PET. لهذه المادة خصائص رياضية جيدة في الحالة المنصهرة، ويتأثر لزوجتها بالضغط أكثر من درجة الحرارة. هذا يعني أنه في عملية الإنتاج، يقوم المهندسون بتحسين سيولة المصهور بشكل أساسي عن طريق تعديل الضغط بدلاً من درجة الحرارة، وذلك لضمان استقرار جودة المنتج.

تجدر الإشارة إلى أن درجة حرارة الانتقال الزجاجي لبوليمر (PET) تبلغ حوالي 165 مئوية، ودرجة تبلور (PET) تتراوح بين 120 مئوية و220 مئوية. إن خاصية الأداء الحراري هذه تؤثر بشكل مباشر على تحديد معايير عملية الإنتاج، كما أنها تعد من العوامل الرئيسية التي تضمن سلامة المنتج.

02خيارات السلامة: استخدام البلاستيك (PET) في تعبئة المواد الغذائية

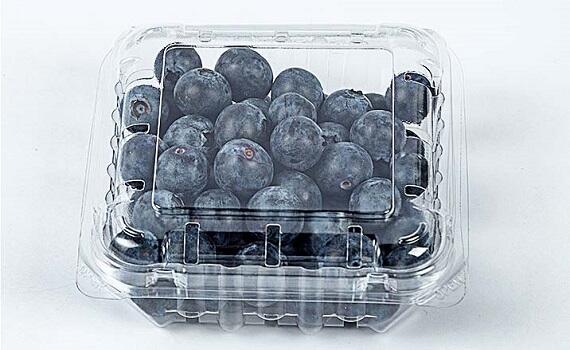

لا يحتوي بلاستيك (PET) على مواد ضارة مثل الفثالات والبيسفينول أ، مما يجعله معترفًا به على نطاق واسع كمواد آمنة للاتصال بالغذاء في جميع أنحاء العالم. في الوقت الحالي، حيث أصبحت سلامة الغذاء أمرًا بالغ الأهمية، أصبح (PET) هو الخيار الرئيسي لتغليف الأغذية والمشروبات. ويمكنك رؤية تغليف (PET) في مياه الشرب المعدنية والمشروبات الغازية والزيوت النباتية والتوابل.

يتمتع مادة الـ PET بأداء ممتاز في العزل، حيث يمكنها منع اختراق الغازات والبخار والزيوت والروائح بشكل فعال. تضمن هذه الميزة بقاء محتويات التغليف طازجة، ومنع دخول الملوثات الخارجية، كما تمنع تطاير رائحة المحتويات.

في تغليف الأغذية، يتمتع الـ PET شفافية تزيد عن 90%، مما يجعله جذاباً من الناحية الجمالية، ويتيح للمستهلكين رؤية حالة المحتويات بوضوح. وتوفر قدرته الطبيعية على حجب الأشعة فوق البنفسجية حماية إضافية للمنتجات الحساسة للضوء.

تم الاعتراف بسلامة مادة البولي إيثيلين تيريفثاليت (PET) باعتبارها مادة تلامس الأغذية من قبل إدارة الأغذية والعقاقير الأمريكية (FDA) وهيئة سلامة الأغذية الأوروبية وسلطات عالمية أخرى. عندما تختار زجاجة مخصصة من PET، فإنك تختار معيار سلامة معترف به عالميًا.

03 الخامسة الأساسية المزايا: لماذا تختار بلاستيك PET س

>ه ممتازة الخواص الميكانيكية الممتلكات يس

إن مقاومة الصدمة لزجاجة البلاستيك من مادة الـ PET تبلغ 3 إلى 5 مرات مقارنة بمواد الفيلم الأخرى، كما أنها تتميز بمقاومة ممتازة للطي. وهذا يعني أن التغليف المصنوع من مادة PET لا ينكسر بسهولة أثناء النقل أو الاستخدام، مما يوفر حماية موثوقة لمنتجاتك. كما تتميز مادة PET بصلابة سطح عالية ومقاومة للتآكل ويمكنها تحمل بعض التأثيرات الخارجية.

>استقرار كيميائي قوي

تتميز مادة PET بمقاومتها للزيوت والدهون والأحماض والقواعد المخففة، ولها مقاومة جيدة لمعظم المذيبات. هذه الخاصية تجعل مادة PET خيارًا مثاليًا لتغليف المنتجات مثل زيوت الطعام ومستحضرات التجميل والمنظفات وغيرها. إن مقاومتها للتآكل الكيميائي تضمن عدم حدوث تفاعلات سلبية بين العبوة والمحتوى داخلها.

>صحة وسلامة عالية

البولي إيثيلين تيريفثاليت (PET) نفسه غير سام وخالي من النكهة، وهو يلبي متطلبات النظافة الخاصة بالتعبئة والتغليف ذات الدرجة الغذائية. في عملية الإنتاج، لا يتم إضافة مواد مضافة ضارة إلى البلاستيك المصنوع من مادة PET، ويمكنه أن يكون على اتصال مباشر مع الطعام والأدوية، مما يوفر حماية لصحة المستهلكين.

>صديق للبيئة وقابلة لإعادة التدوير

تعتبر مادة PET واحدة من المواد التي تتميز بأعلى معدل استرجاع بين البلاستيكيات، ويمكنها تحقيق إعادة تدوير مغلقة الحلقة من "زجاجة إلى زجاجة". مقارنةً ببلاستيكيات أخرى، فإن عملية إعادة تدوير PET ناضجة ولها قيمة عالية لإعادة التدوير، وهي تتماشى مع مفهوم الحفاظ على البيئة في الاقتصاد الدائري اليوم.

>خفيفة الوزن واقتصادية

تتميز مادة PET بقوة عالية، مما يسمح بتصميم الجدران الرقيقة وتقليل وزن التعبئة والتغليف وتكاليف النقل. كما أن سعر المواد الخام واستهلاك الطاقة في الإنتاج منخفضان نسبيًا، مما يوفر حلول تعبئة فعالة من حيث التكلفة للعلامات التجارية.

04 مقارنة شفافة: الفرق في الأداء بين PET وبقية البلاستيكيات

تشمل البلاستيكات التعبئية الشائعة في السوق PET وPP وPE وغيرها. وفهم الاختلافات بين هذه المواد سيساعدك على اتخاذ خيارات أكثر إدراكًا.

بالمقارنة مع PP، فإن مقاومة الشد لـ PET تبلغ ضعفها إلى ثلاثة أضعاف مثيلتها في PP، كما أن مقاومته لتقدم السن تزيد أربعة أضعاف عن PP. وهذا يعني أن تغليف PET يتمتع بعمر خدمة أطول، ولا يصبح هشًا أو يتحلل بسهولة مع مرور الوقت. كما أن شفافية PET ولمعانه أفضل من PP، مما يجعل مظهر المنتج أكثر جاذبية.

مقارنةً ببولي الإيثلين (PE)، يتمتع البولي إيثيلين تيريفثاليت (PET) بصلابة أعلى وقدرة أكبر على الحفاظ على الشكل، ولا يتشوه بسهولة. خاصية مقاومة انتقال الغاز في مادة البولي إيثيلين تيريفثاليت (PET) أفضل بكثير من بولي الإيثلين (PE)، وهو أكثر ملاءمة للمشروبات الغازية والمنتجات الأخرى التي تحتاج إلى حفظ الغاز. بينما ليونة بولي الإيثلين (PE) تجعله أكثر ملاءمة لتصنيع الزجاجات عن طريق البثق وأنواع التعبئة الخاصة الأخرى.

من حيث إعادة التدوير، فإن مسار إعادة تدوير مادة الـ PET أكثر وضوحًا وكفاءة. فبعد جمع زجاجات الـ PET، يمكن تحقيق إعادة تدوير تصلح للاستخدام الغذائي من خلال عمليات متقدمة من التنظيف والفرز والتحبيب (إعادة تدوير "من زجاجة إلى زجاجة")، في حين تُستخدم معظم إعادة تدوير مادة الـ PE في تطبيقات تنقص من قيمتها.

تجعل شفافية مادة الـ PET وقوتها وإمكانية إعادة تدويرها بارزة لها في مجال التعبئة والتغليف، لتكون الخيار الأول للعلامات التجارية والمستهلكين.

05 التصنيع الدقيق: نقاط رئيسية في عملية إنتاج زجاجات البلاستيك PET

يحتاج إنتاج زجاجات بلاستيكية عالية الجودة من نوع PET إلى تقنية متخصصة وتحكم صارم في العمليات. وبصفتنا خبراء في إنتاج الزجاجات البلاستيكية المخصصة، فإننا نتحكم بدقة في كل مرحلة من مراحل الإنتاج.

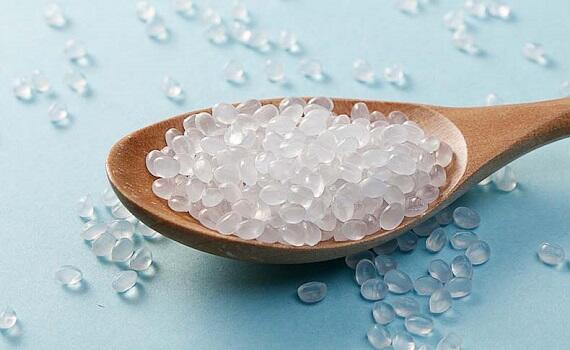

المعالجة الأولية للمواد الخام هي المفتاح الأساسي. إن حبيبات البولي إيثيلين تереيفثالات (PET) حساسة للغاية للرطوبة عند درجات الحرارة العالية، ويجب تجفيفها تمامًا قبل المعالجة. عادةً ما تُجفف على حرارة 150 مئوية لأكثر من 4 ساعات، أو على حرارة 170 مئوية لمدة 3-4 ساعات. قد تؤدي الرطوبة الزائدة إلى انخفاض وزن الجزيئات لبوليمر PET، وتسبب هشاشة وتغير لون المنتجات.

إن مرحلة الحقن بالقالب مهمة أيضًا. يتم التحكم بدرجة حرارة الانصهار بين 270-295 مئوية، و290-315 مئوية لبوليمر PET المعزز بالألياف الزجاجية (GF-PET). يجب أن تكون سرعة الحقن سريعة، وعادةً ما تكتمل خلال 4 ثوانٍ لمنع التصلب المبكر.

تصميم القالب له أهمية كبيرة أيضًا. نستخدم نظام قوالب ذات نظام تغذية ساخن (Hot Runner)، مع تركيب حاجز حراري بسماكة 12 مم بين القالب ولوحة آلة الحقن. تم تصميم نظام العادم بدقة لضمان تهوية كافية والحد من حدوث الوميض (Flash).

من حيث ضمان الجودة، فإننا نتبع مبدأ "أقصر وقت إقامة" لتجنب تقليل الوزن الجزيئي الناتج عن بقاء المادة عند درجات حرارة عالية لفترة طويلة جدًا. وفي الوقت نفسه، يجب التحكم بدقة في نسبة المواد المعاد تدويرها بحيث لا تتجاوز 25%، ويجب تجفيف المواد المعاد تدويرها تمامًا.

06 إعادة التدوير الخضراء: القيمة البيئية وإعادة تدوير البلاستيك PET

في الوقت الحالي، الذي أصبحت فيه التنمية المستدامة إجماعًا عالميًا، تُظهر بلاستيكيات PET خصائص حماية بيئية ممتازة. يعد PET أحد أنواع البلاستيك ذات أعلى معدل استرداد، وقد أصبحت تقنيات إعادة تدويره متقدمة بشكل كبير.

إن إعادة التدوير المتقدمة من "الزجاجة إلى الزجاجة" للحصول على درجة تغذية آمنة تعد نموذجًا لاقتصاد الدائرة المغلقة لبلاستيك PET. يمكن استعادة زجاجات PET المهترئة عبر عمليات التكسير والتنظيف والتجفيف والفرز وتصنيع الحبيبات. وتقوم هذه العملية بإزالة الملوثات وزيادة اللزوجة، مما يجعل مادة البلاستيك المعاد تدويرها (RPET) تتوافق مع معايير السلامة الخاصة بالاستخدام في المنتجات الغذائية.

ويمكن لكل طن متري من رقائق زجاجات PET المستعادة أن يقلل انبعاثات CO₂ بمقدار 1.871 طن ويوفّر 6 أطنان من موارد النفط. وإذا تم زيادت كمية النفايات البلاستيكية PET المعاد تدويرها عالميًا إلى 10 ملايين طن سنويًا، فهذا يعادل زيادة قدرة الامتصاص الكربوني لمساحة 660000 هكتار من الغابات.

نستجيب بنشاط لاتجاه الحفاظ على البيئة، وندمج مواد PET المعاد تدويرها في إنتاج الزجاجات المخصصة. وقد قام كل من Coca Cola وعلامات تجارية دولية أخرى بطرح زجاجات PET جديدة تحتوي على بعض المواد الخام النباتية، وتخطط لإنتاجها بكميات كبيرة. وهذا يثبت أن مواد PET لديها آفاق واسعة في مجال التعبئة والتغليف المستدام.

07 خبير تخصيص: حلول تعبئة PET مخصصة لك

بصفتنا موردًا محترفًا في مجال تخصيص تعبئة PET، لدينا فهم عميق لاحتياجات التعبئة في مختلف الصناعات. سواء كانت الأغذية والمشروبات أو العناية الشخصية أو الرعاية الطبية أو المنتجات المنزلية، يمكننا توفير حلول تعبئة PET آمنة وموثوقة.

لدينا خط إنتاج متقدم لقوالب الحقن الخاصة بالحيوانات الأليفة، وفريق تقني محترف، ونتبع بدقة نظام إدارة الجودة ISO ومعايير الإنتاج الخاصة بالمواد الغذائية. من شراء المواد الخام حتى تسليم المنتجات النهائية، يتم مراقبة كل مرحلة بدقة لضمان سلامة المنتجات وموثوقيتها.

من حيث الخدمات المخصصة، نوفر:

·تصميم متنوع لأنواع الزجاجات: زجاجات مخصصة بسعة مختلفة تتراوح من 15 مل إلى 5 لتر

·تعديل وظيفي احترافي: أغطية مقاومة للعبث، هيكل مقاوم لأشعة UV، خطوط مضادة للانزلاق وغيرها من الوظائف الخاصة

·عملية معالجة السطح: خيارات تزيين سطحية مثل الطباعة الحريرية، التصفيح الذهبي، وضع الملصقات وغيرها

·خطة الحماية البيئية: استخدام قوارير PET المعاد تدويرها والمعتمدة للمواد الغذائية لمساعدة العلامات التجارية على تحقيق أهداف الاستدامة

نوصي العملاء بمراعاة خصائص المنتج وعملية التعبئة وظروف التخزين وموقع العلامة التجارية والعوامل الأخرى عند اختيار زجاجات مخصصة للحيوانات الأليفة. سيقدم لك فريق مهندسينا نصائح احترافية لتحسين تصميم التغليف والتوازن بين الوظائف والجاذبية والتكلفة.

مع زيادة القلق العالمي بشأن تلوث البلاستيك، أصبحت مادة PET المادة المفضلة للتغليف المستدام بفضل معدل الاسترداد العالي والقيمة الكبيرة في إعادة التدوير. من إعادة تدوير الدرجة الغذائية إلى الابتكارات المستوحاة من النباتات، تواصل هذه المادة متعددة الوظائف التطور لتلبية متطلبات حماية البيئة في العصر الحديث.

عندما تختار زجاجة PET مخصصة، فإنك لا تختار فقط عبوة، بل تختار ضمانًا لجودة المنتج والتزامًا بصحة المستهلك ومسؤولية تجاه مستقبل الكوكب. دعونا نتعاون لتقديم قيمة مضافة لعلامتك التجارية من خلال تغليف PET الآمن والموثوق.