Innovative Cosmetic Packaging: How Does Heat Induction Sealing Gasket Ensure Product Safety and Freshness?

In the field of cosmetics and skincare, the freshness, safety, and user experience of products directly determine the brand's reputation and consumer trust. However, many companies are still struggling with issues such as leakage, pollution, and short shelf life - which not only cause economic losses but also damage brand image.

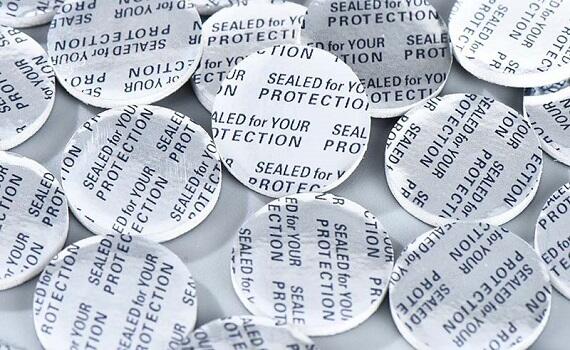

As a revolutionary solution in the packaging field, thermal induction sealing gaskets (also known as electromagnetic induction aluminum foil sealing gaskets) are rapidly becoming the "invisible guardians" of high-end cosmetic packaging. It forms a molecular level sealing barrier at the bottle mouth through the principle of electromagnetic induction heating, providing multiple protections for the contents.

01 Impermeable Barrier: Preventing Leakage and Oxidation

Thermal induction sealing gaskets are usually composed of multiple layers of composite structures, including PE/PET heat sealing layer, aluminum foil layer, barrier functional layer, and backing cardboard. When the electromagnetic field acts on the aluminum foil, it instantly heats up and melts the heat sealing layer, making it seamlessly adhere to the bottle mouth. This sealing method can completely prevent the penetration of air, water and pollutants, and is especially suitable for easily oxidized essence oil, vitamin C derivatives or natural active ingredient products.

Experimental results have shown that using a three-layer barrier structure (such as polyamide+polyvinylidene chloride+weather resistant coating) for gaskets can increase the barrier efficiency of highly corrosive components such as hydrofluoric acid and xylene by over 80%, avoiding the deterioration of contents due to slight leakage at the bottle mouth.

02 Double the Freshness Locking Power: Extend the Product's Active Life Cycle

The active ingredients in skincare products, such as peptides and antioxidants, are extremely sensitive to light, heat, and oxygen. Traditional mechanical bottle caps are difficult to avoid slow deactivation of ingredients due to the presence of micro gaps. And the heat induction sealing gasket achieves triple preservation by completely sealing with airtightness:

·Damp proof and humidity control: block the invasion of ambient water vapor and protect water sensitive ingredients such as freeze-dried powder and facial mask powder;

·Oxygen isolation and volatilization prevention: The aluminum foil layer blocks oxygen permeation, maintaining the stability of volatile components in essential oils and ethanol based products;

·Light protection: Aluminum foil reflects ultraviolet rays, reducing the decomposition of photosensitive components.

The actual measurement shows that the active retention rate of the essence solution using this technology after opening is increased by 40%, and the shelf life is extended by more than 6 months.

03 Safety and Hygiene: Building a Sterile Defense Line

Once cosmetics are contaminated by microorganisms, they may cause skin allergies or even infections. Thermal induction sealing gaskets provide key guarantees during production and filling processes:

·Non contact sealing: Electromagnetic induction heating does not require direct contact with the bottle mouth, avoiding the risk of secondary pollution;

·Material safety: Using FDA certified PE heat sealing layer and solvent-free adhesive, with 0 dissolution and 0 odor, passing the EU EC No. 1935/2004 food grade migration test;

·Preservative reduction: Due to improved sealing, some formulations can reduce dependence on irritating preservatives such as phenoxyethanol.

>Case: After a certain organic brand switched to heat sensitive sealing in toner packaging, the customer complaint rate decreased by 62%.

04 Anti Counterfeiting and Anti Tampering: Enhancing Consumer Trust

Thermal induction sealing is not only a physical barrier, but also a part of the "brand safety strategy":

·Immediate damage upon opening design: When opened for the first time, the strong adhesion between the gasket and the bottle mouth causes the aluminum foil layer to tear and cannot be restored;

·Customized printing: Brand logos, anti-counterfeiting codes, or traceability information can be printed on the aluminum foil surface to curb the circulation of counterfeit products;

·Anti theft and leak detection: Visualization of sealing status allows consumers to quickly confirm whether the product has been opened or adulterated.

This feature is especially applicable to high value-added products such as high price essence and ampoule, so as to enhance purchase confidence.

05 User Experience Upgrade: Balancing Convenience and Environmental Protection

Modern packaging needs to balance functionality and user experience. Innovative design of thermal induction sealing gasket hits the pain point:

·Easy to open and non stick: using weakly adhesive backing cardboard, the aluminum foil layer fully adheres to the bottle mouth after opening, without residual debris (compared to traditional foam gaskets);

·Silent and environmentally friendly: Some models use biodegradable PE film, which has a 35% lower carbon footprint than PVC gaskets;

·Strong adaptability: Supports various bottle materials such as PE, PET, glass, ceramics, etc., with flexible customization of diameters ranging from 5mm to 120mm.

·User insight: 87% of consumers believe that "easy to open and reliable sealing" is the core requirement for high-end skincare packaging.

Why Are Global Brands Shifting Towards Heat Sensing Seals?

According to the 2024 Beauty Packaging Trends Report, brands that adopt intelligent sealing technology have reduced e-commerce return rates by 27%, and the proportion of customer complaints involving leakage/deterioration has decreased by more than half. Whether it is dropper bottle essence, face cream jar, or sunscreen spray, the thermal induction sealing gasket, through the combination of material science and engineering design, escorts the whole life cycle of the product: from the filling line to the consumer dresser, every link is resisting risks and locking freshness.

>Expert opinion: "In the era where active ingredients are king, packaging is no longer a container, but the core of the 'preservation system'. Thermal induction sealing builds a defense line at the molecular level, which is one of the most critical evolutions of cosmetic packaging materials in the past decade

Call for Action

As a professional personal care product factory in China, we offer a full range of thermal induction sealing solutions:

♦Compatible with various bottle types and materials

♦Support customized sizes, printing, and barrier levels

♦Compliant with ISO 15378 drug packaging certification